- Home

- Processes and Services

Processes and Services

-

- Investment Casting

As a professional casting manufacturer, we focus on casting technology and casting service. As a well-known for Industrial casting, investment casting (also called lost wax casting or precision casting), today, is a main and high quality method to manufacture precision metal parts and components. We have rich experience in this business to give you custom metal casting solutions.

-

- Sand Casting

Sand casting is a traditional casting process in which molten metal is poured into a mold made from sand. Because of the flexible characteristics of sand casting, it is used to create a variety of parts with complex geometries, and it is compatible with nearly any alloy. Sand casting is not limited by the size, shape, or complexity of the cast parts. It is also a low-cost casting option with a short production cycle.

-

- Fast product development

Relying on years of experience in casting, advanced industrial CT equipment, reverse engineering and strong mold design ability, Yanshan Precision Machinery co., Ltd can shorten the development cycle of new products in six weeks to strength ability of quickly responding to market changes for customers. Yanshan Precision Machinery co., Ltd could produce complex castings with high quality and high precision to meet the diversified requirements of customers.

-

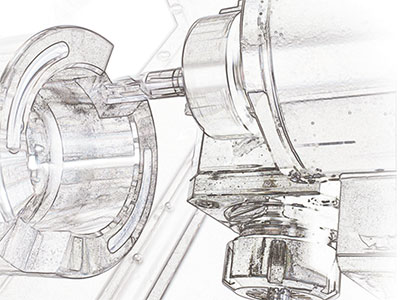

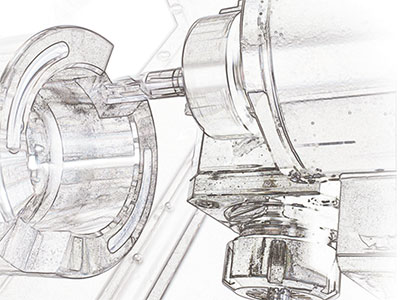

- Machining Solution & Heat Treatment

Here at Yanshan Precision Machinery Co., we also provide heat treatments, machining, and other post casting services. Our production base has an annual production capacity of more than 3,000 tons with a variety of casting equipment and processing capabilities. We have CNC lathes, machining centers, CNC wire cutting machines, and other finishing equipment.